Processing technology

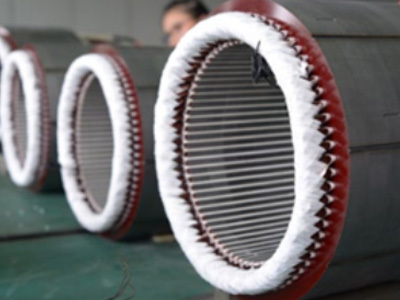

The company specializes in providing systematic supporting services for customers such as DC/AC motors, generators, new energy motors, stator and rotor cores, and rotor die-casting.

We use advanced processing equipments, to produce motor iron cores professionally, and select production processes and

equipments according to the customer demand.

At present, our capacity of iron cores of silicon steel reaches 50,000 tons a year.

Scope of equipment tonnage:Compound stamping equipments 25 T - 400 T/ Accurate high-speed stamping equipments 80 T - 450 T /

Number of equipments: compound stamping equipment 32 PCS / Accurate high-speed stamping equipments 9 PCS

We use advanced die-casting equipments to provide customers with high-quality aluminum

die-casting products.Scope of equipments tonnage: 180 T - 560 T Number of equipments: Horizontal die-casting machines 4 PCS

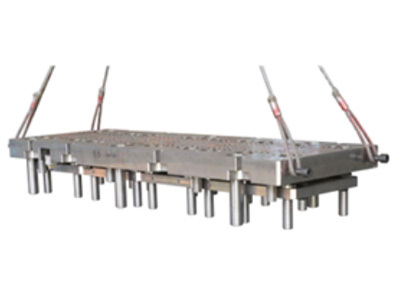

The company has a group of professional mould designers and experienced mold makers to provide a potent guarantee for the production

of various high-accuracy moulds.

The company provides efficient service of coil inserting of iron core to meet customer demand,

and provides all customers with rapid, highly efficient, and high-quality services. The company has 6 production lines of automatic

coil inserting of iron bar. Annual capacity of automatic coil inserting line: 1 million pieces Processing range: diameter of iron core 45 mm - 160 mm height of iron core 6 L - 120 L

The company adheres to the quality principle

of“careful, attentive, meticulous, and quality

assured”to serve customers, and continues to improve the product quality to provide customers

with high-quality products and services.

Inspection equipment:

Hexagon Three-coordinates Measuring Instrument

Serein Optical Measuring Instrument

Rotor Dynamic Balance Detector

Broken Aluminum Rotor Bar Detector

Buckle Riveting Pulling Force Detector

Salt Spray Tester

Stator Integrated Test Bed